The calibration of powertrains is associated with high costs and time expenditures due to the complexity of these systems. To determine the optimal settings of the powertrain control units with regard to outcomes such as performance, fuel economy and emissions, the characteristics of the powertrain must be accurately measured. Due to the many degrees of freedom, a complete survey is extremely time consuming and often impractical. The use of model-based methods based on design of experiment (DOE) solves this problem.

Using this approach, the behavior of a complex system - such as the combustion engine – is identified on the basis of a few, optimally distributed measurements and represented by a mathematical model. So far, model-based methods are used in ECU calibration only in exceptional circumstances: The current models based on polynomials or neural networks are either not sufficiently accurate for many tasks or require special modeling skills.

ETAS ASCMO – A universal solution for model-based calibration

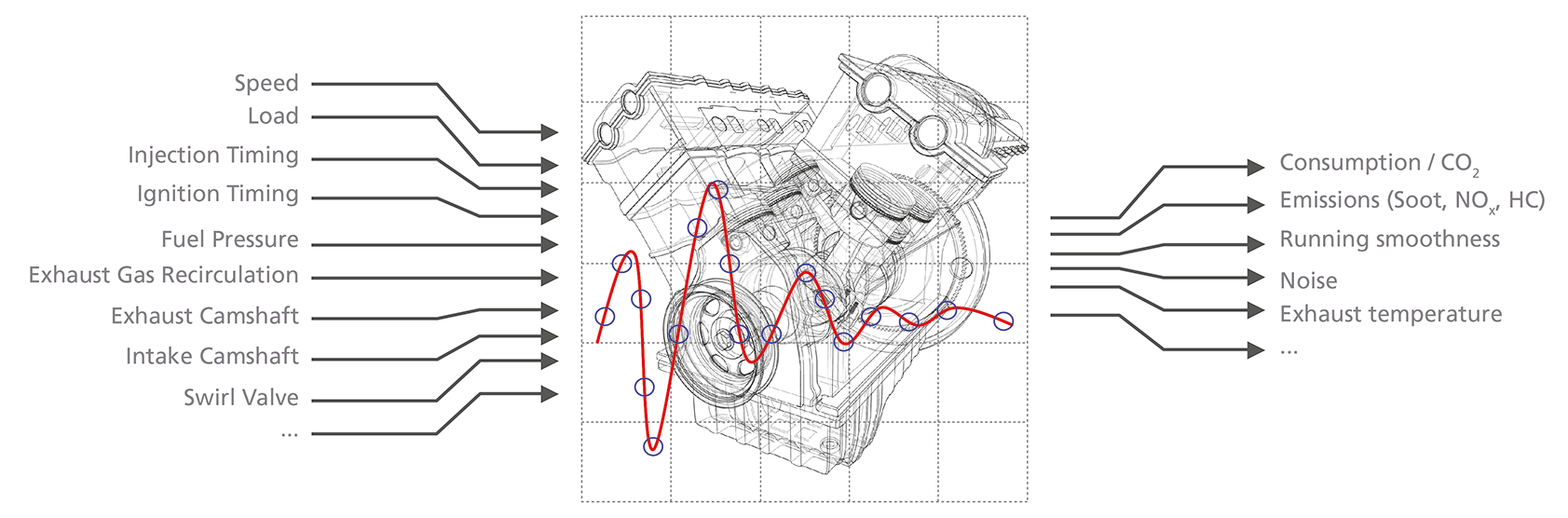

The accurate modeling of the system behavior based on a small number of measurements is a central element of ETAS ASCMO. This tool uses new data-based methods which make it possible to represent characteristic engine behaviors such as consumption, engine-out emissions and exhaust gas temperature as a function of the operating conditions (speed, load, engine temperature) and the settings of calibration parameters (for example, ignition, fuel injection, camshaft position, etc.) on the basis of a few measurements in a largely automated manner in the form of a mathematical model.