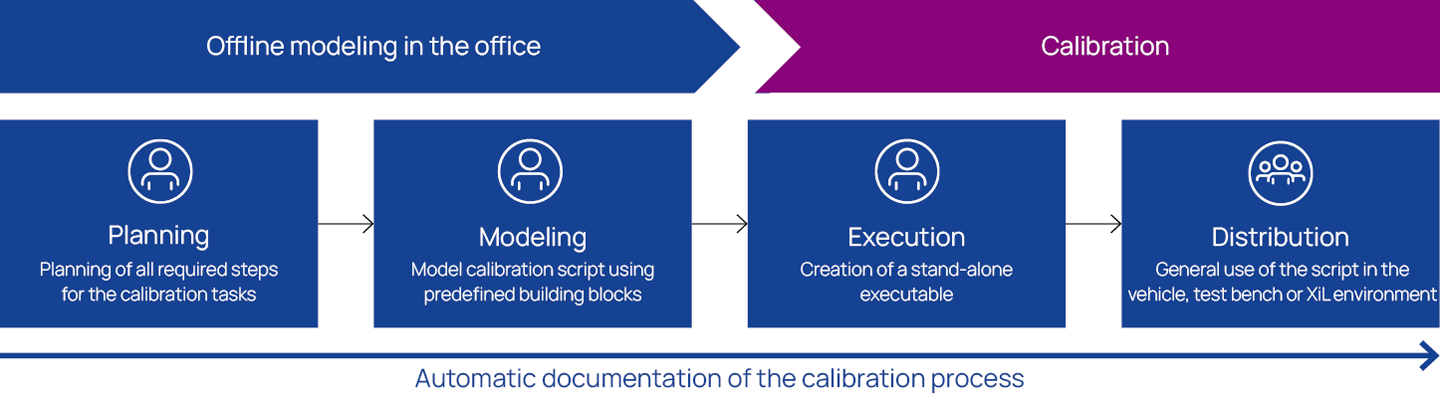

INCA-FLOW can be used in the office to plan and design calibration and validation tasks. The graphical editor provides an intuitive interface for defining calibration procedures without requiring programming skills. The executable specification also serves as documentation.

In the vehicle, INCA-FLOW controls INCA to execute the procedure and guides the engineer through the calibration task. This approach results in repeatable, high-quality results and high efficiency for all vehicle variants and software releases.

INCA-FLOW is a software solution from IAV GmbH and is exclusively sold and supported by ETAS.

Wide range of applications

INCA-FLOW can be used to:

- Automate procedures used to calibrate ECU functions

- Validate and document procedures

- Analyze measurement data

- Perform guided optimization of control functions

Advantages over conventional methods

Automation of in-vehicle calibration generally relies on conventional programming methods. This approach often fails due to its lack of flexibility. To respond quickly to current requirements in an ongoing project, calibration engineers must be able to adapt automation procedures as fast as possible.

INCA-FLOW offers many advantages over conventional programming language-based automation approaches.

- INCA-FLOW is designed for calibrators. It facilitates the automation of procedures without requiring any programming skills

- The graphical representation of algorithms is easy to understand even for less experienced calibrators. This simplifies maintenance of existing calibration procedures

- Libraries with comprehensive collections of ready-to-use MCD methods facilitate the creation of very efficient procedures