New MDF4 measure data format

The industry proven MDF3 measure data format has been widely used for many years to store, exchange and analyze measure data for automotive system development purposes. However, taking into account the requirement for faster data exchange between development tools as well as the need for higher data volume, and also considering that more and more customer specific information was introduced in the format, it became evident that MDF3.x had reached its limits.

As a consequence, MDF4 was created to extend and unify the existing and widely used MDF3.x variants and to overcome limitations such as file size, global time information, handling of events and meta-data information for recording systems. To provide for maximum support by measure data analysis tools, MDF4 - unlike the previous versions of the MDF format - was defined and is maintained by the ASAM Association for Standardisation of Automation and Measuring Systems.

Applications using MDF4 can now record more data to one file, due to the extended file size that has increased from 4 GB to 16 GB. Other significant benefits of using MDF4 are that measurement data can be accessed faster than before and that the change-history can now be stored in the measure data file. Furthermore, the in-built data reduction enables the user to store already reduced data for a fast data access.

The ETAS solution

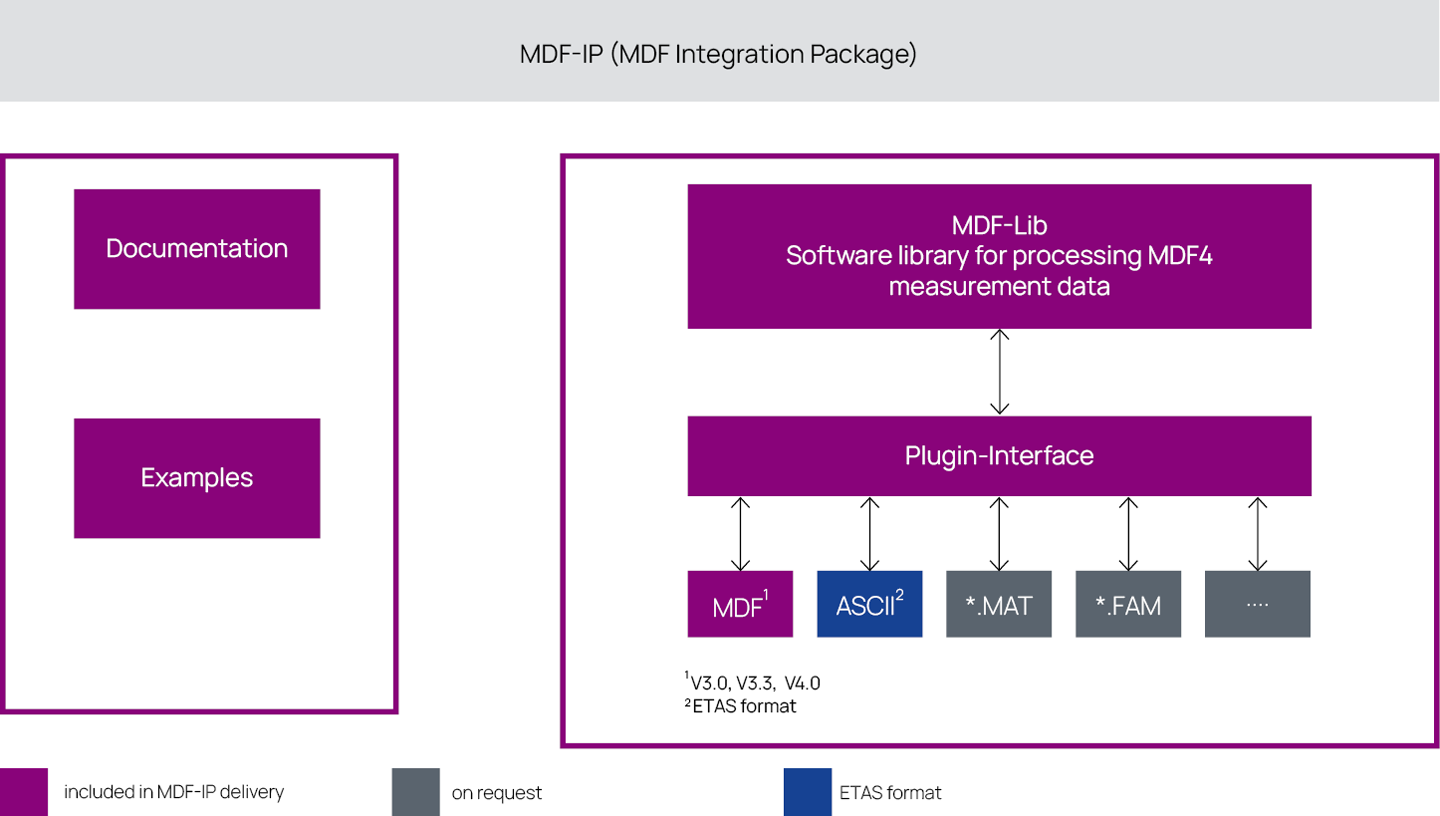

ETAS offers a generic software library, which is fully compliant with the new ASAM MDF4 standard. The library is part of MDF-IP and is used in ETAS tool applications, such as INCA V7 and MDA V7. The software library has been designed also to be integrated into many different working environments in which measurement files are generated or used. MDF-IP supports an open interface that can be used by any data generating system to write measurement files in MDF4 format and by any data analyzing system to read measurement files in MDF4 format. Furthermore, MDF-IP provides a generic interface for integrating additional measurement file formats. Customer specific software applications, e.g. format converters, can use this interface.

Benefits of using MDF-IP

- Standardized data exchange between in-house, third-party, and ETAS tools

- Proven technology for measure data format interpretation and generation

- Interface for application programming encapsulates measurement data format handling completely

- Fast integration of the new MDF4 standard with in-house and third-party applications

- Less development and maintenance costs due to the integration of a standard component