Embedded Artificial Intelligence

New capabilities in engine controls development

The latest engine control units (ECUs) come with a new generation of high-performance system-on-chips to increase available computational power. These devices have the ability to provide onboard resources to support unexpected feature growth and on-demand customer requirements. Infineon and ETAS worked together with Ford Research to demonstrate the use of data-driven modeling algorithms directly on the ECU as a remedy for the limitations of classical control strategies.

More stringent emissions legislation and the increasing complexity of recent technologies such as hybrid electric vehicles and autonomous driving are pushing the need for more advanced control functions in engine management systems. Traditional control strategies and virtual sensors introduced on ECUs have been limited to calibration maps of up to two input dimensions to deliver the desired engine behavior for various operating conditions. Higher-dimensional relationships are possible when combining a map’s output with other calibrations. However, only two input parameters can be processed simultaneously on the ECU core. Considering the requirements of upcoming ECU controls and the necessary calibration effort within the development cycle, the map-based approach is only applicable to a limited extent. As a remedy, data-driven models have the potential to replace and outperform traditional map-based structures in cases where multidimensional and non-linear behaviors cannot be captured with sufficient accuracy.

Data-driven system identification ETAS ASCMO

Data-driven modeling refers to approximating the input/output behavior of a physical system through the aid of mathematical equations. A set of model parameters is inferred from a representative set of measurement samples collected under operating conditions. ETAS ASCMO uses Gaussian Processes, a Bayesian modeling approach, to generate high-fidelity data-driven models. The model creation is executed automatically and does not require any parameterization effort by the user. The tool may be used without any knowledge of the underlying principles and may deliver similar or even better model accuracies than comparable data-driven solutions. For the model’s application in embedded environments, ETAS ASCMO provides a model compression feature to minimize the computational impact and to guarantee real-time execution.

Infineon’s hardware accelerator Advanced Modeling Unit (AMU)

ECU function developers are faced with limitations when implementing complex data-driven modeling algorithms on microcontroller-based architectures. The new hardware accelerator Advanced Modeling Unit (AMU), which was developed with intellectual property from Bosch, is a floating-point coprocessor to increase performance of critical applications by off-loading the computation from the central processing unit (CPU). The AMU is available on Infineon TriCoreTM AURIXTM TC3x microcontrollers and provides hardware logic to perform exponential function calculations (e.g., Radial Basis Function – RBF) necessary to run ETAS ASCMO models on chip without software and CPU resources. An example for a RBF-based use case can be a virtual sensor calculation, which, in comparison to a software implementation on the main TriCoreTM CPU, achieved hardware acceleration by a factor of greater than 30 [1].

ETAS ASCMO and AMU within the application

In traditional development methods, models are developed based on system physics and fundamental engineering principles. These models are generally designed once per system type and then reused across many applications. A lot of data is collected in order to gain sufficient understanding of the system so it can be modeled as part of the development process. The intent is for the models to be identical across the various applications and differ only in the calibration for a specific application.

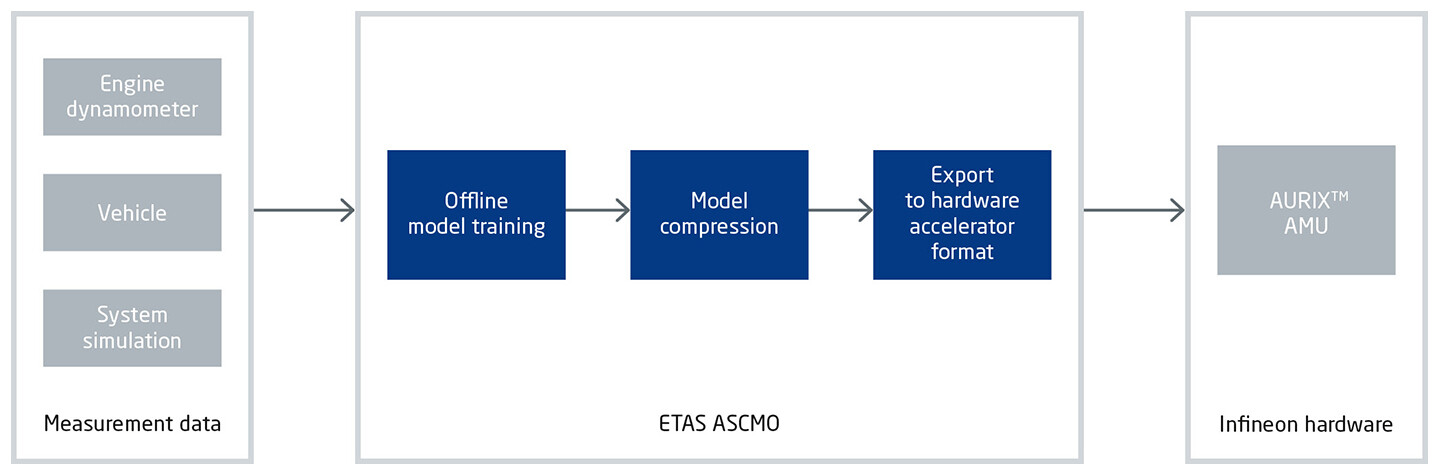

Software development with ETAS ASCMO and AMU is slightly different from traditional methods (Fig. 1). Only the inputs that may contribute to a particular output need to be identified during software development; the specific relationship between inputs and output is not needed. Required data for training and testing the model is collected from engine dynamometers or instrumented vehicles. Training and evaluating the models in ETAS ASCMO is done offline. The training data size and compression ratio in ETAS ASCMO have trade-offs that impact execution time, required memory size, and output precision. Validation of the model accuracy based on statistical measures is also done in ETAS ASCMO. If the output precision is sufficient, then the model is exported to the AMU data format, and subsequently deployed into ECU hardware.

Example and performance analysis

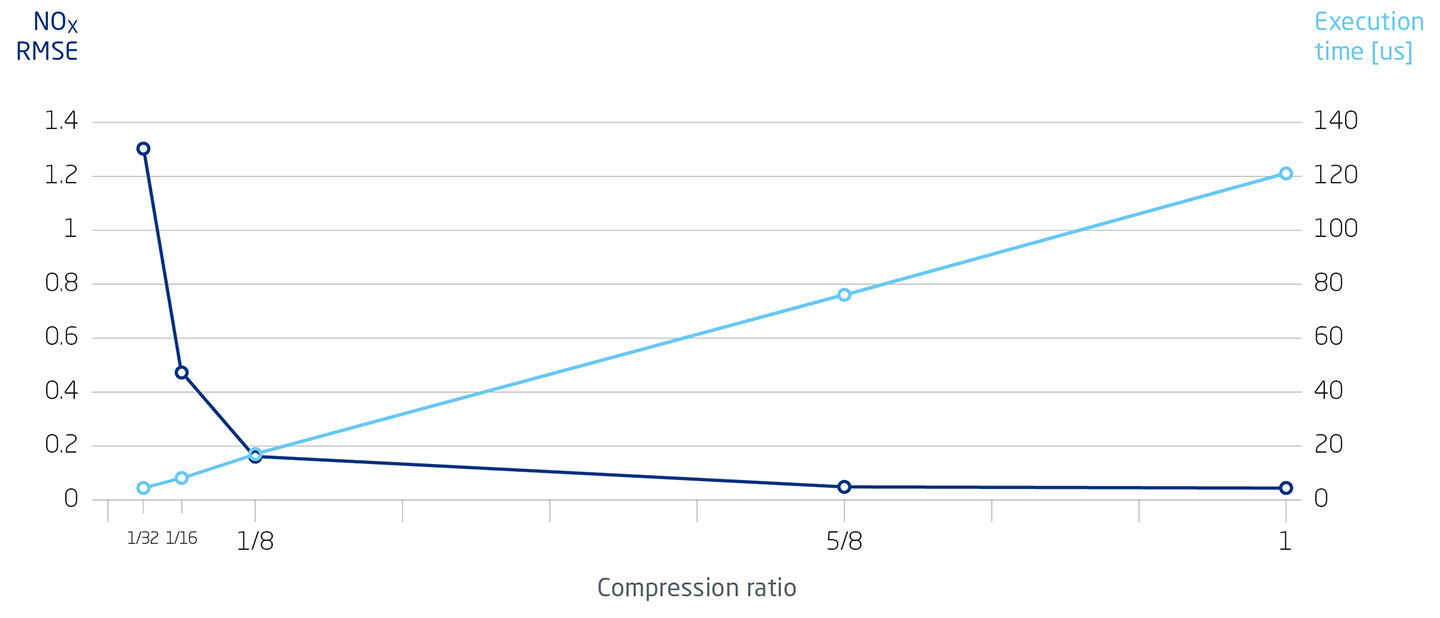

The results of a non-production intent example to calculate engine NOx emissions are summarized in Fig. 2. The AMU execution time of the uncompressed model was about 120 µs. One conclusion from Fig. 2 is the linear relationship between compression ratio of the model and execution time. The gradient of the skew line will depend on the number of inputs. Another take away is the non-linear trade-off between model compression and the model’s root mean square error (RMSE). The RMSE will drastically increase for larger compression factors, in other words, less than 1/8 in this example. This reduction in model size will result in shorter execution times while maintaining the original model behavior without a significant loss in accuracy. The RMSE requirement of the particular application will be driving the compression ratio.

Other applications of ETAS ASCMO and Infineon’s AMU are available in the literature, for example, for volumetric efficiency and exhaust gas recirculation modeling [2], which adds evidence demonstrating the benefits of this new approach in series production software development.

Summary

As ECU functions become increasingly complex, using data-driven modeling will considerably reduce the overall time and effort required while offering better quality and ensuring that the application is clearly understood. ETAS ASCMO gives the user the ability to generate highly accurate behavioral models with a simple click of a button. Infineon AURIXTM AMU is an enabler to execute ETAS ASCMO models in real time without having a significant impact on the ECU’s main core. Hardware acceleration of the AMU and model compression in ETAS ASCMO are key to efficiently implementing data-driven models on the ECU.

Authors

Chinh Nguyen is System-on-Chip and In-vehicle Compute Research Engineer at Ford Motor Company.

Tobias Gutjahr is Program Manager at ETAS Inc.

Adam Banker is Powertrain Controls Research Technical Expert at Ford Motor Company.

Dona Burkard is In-vehicle Core Software Manager at Ford Motor Company.

Klaus Scheibert is Senior Principal in the System Architectures Team for PT&xEV Applications within Infineon Automotive Microcontrollers at Infineon Technologies AG.

Atilla Bulmus is Lead Principal System Application Engineer for Powertrain at Infineon Technologies North America Corp.

This article is a summary of the findings previously published in [1].

References

[1] Nguyen, C., Gutjahr, T., Banker, A., Burkard, D., Scheibert, K., Bulmus, A. Hardware Supported Data-Driven Modeling for ECU Function Development. SAE Technical Paper 2020-01-1366, 2020.

[2] Nork, B. and Diener, R. AMU-Based Functions on Engine ECUs. In: International Conference on Calibration Methods and Automotive Data Analytics, Expert Verlag, 2019.

Further information

-

Embedded Artificial Intelligence Download

Embedded Artificial Intelligence Download