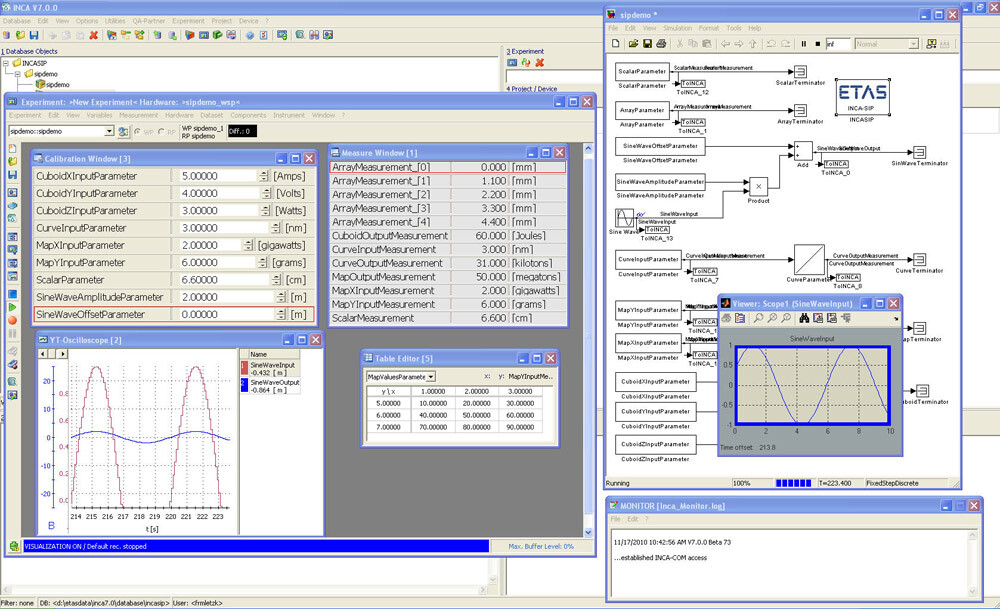

INCA and MATLAB®/Simulink® are linked by INCA-SIP via the XCP protocol. With INCA-SIP, description files and INCA configurations are automatically created in the Simulink environment and transferred to INCA. During simulation, measurements can be recorded and parameters can be changed with INCA. INCA-SIP transfers the changed parameter values to Simulink.

INCA-SIP provides an efficient and automotive-specific environment to Simulink function developers for measurement, calibration and diagnostics. With INCA, experiments and data records can be easily reused and interchanged between application engineers during the development process.

Functions at a Glance

- Early validation, pre-calibration, and testing of Simulink® control models on the PC with INCA

- No prototype hardware or electronic control units required

- Calibration of the Simulink® environment provides for short design iterations

- Easy carry over of existing calibration data

- Use of INCA measurement data from test drives as stimuli for simulations

- Consistent use of INCA measurement and calibration tool throughout the complete control development process