Complex engine simulation using LABCAR-MODEL

Tata Motors’ experience on how ETAS LABCAR-MODEL-VVTB and LABCAR-MODEL-ICE helped validate various features of an engine management system

To meet the government‘s requirements, the validation team of the Passenger Vehicle Business Unit of Tata Motors, decided to use ETAS LABCAR and associated LABCAR models. Using a closed-loop simulation, the team was able to verify the cases that do not require a real vehicle.

The government of India decided to skip an entire regime of emission standards when it announced its plans to shift directly from BS IV to BS VI in 2016. Moreover, this was to be done in four years, by 2020. This regulation not only imposed more stringent emission targets, but also called for next-level OBD (onboard diagnostics) and RDE (real driving emissions) readiness by 2023. Alas, the world’s fourth largest automotive market is not considerate enough to let companies focus exclusively on the powertrain. The peer pressure to constantly roll out and upgrade chassis, body features, infotainment, safety standards (for example ABS: Anti-Lock Braking System is now compulsory for all vehicles), and other comfort features is tremendous.

Given all these demands to contend with, engineers are hard-pressed to validate the entire vehicle communication network and the various features of ECUs in the network. Testing in a real vehicle was the conventional approach for validating various vehicle functionalities. Given the limited availability of prototype and test vehicles, it is always a challenge to deliver test results, validate diff erent scenarios, and execute automation in the available limited time. In order to address these various challenges, the validation team of the Passenger Vehicle Business Unit of Tata Motors decided to use a combination of a HiL system and compatible LABCAR models.

The HiL system enables the Hardware-in-the-Loop (HiL) tests. LABCAR-MODEL-VVTB (Virtual Vehicle Test Bench) simulates vehicles with highly accurate models, while the LABCAR-MODEL-ICE (internal combustion engine) simulates the IC engine. This test environment satisfies nearly 95 percent of the testing needs.

The test system

ECUs from the vehicle are connected to LABCAR. These ECUs are part of a network, much like that of a real vehicle. Along with the simulation models of engine, transmission, and drivetrain, a near-vehicle simulation environment can be achieved.

LABCAR-MODEL-VVTB and LABCAR-MODEL-ICE

Virtual Vehicle Test Bench furnishes the basic model architecture for simulating different components of a vehicle. It consists of a driver model, an environment model, and a vehicle model with engine, dynamics, drivetrain, and transmission. This flexible architecture allows components to be replaced with detailed models when needed.

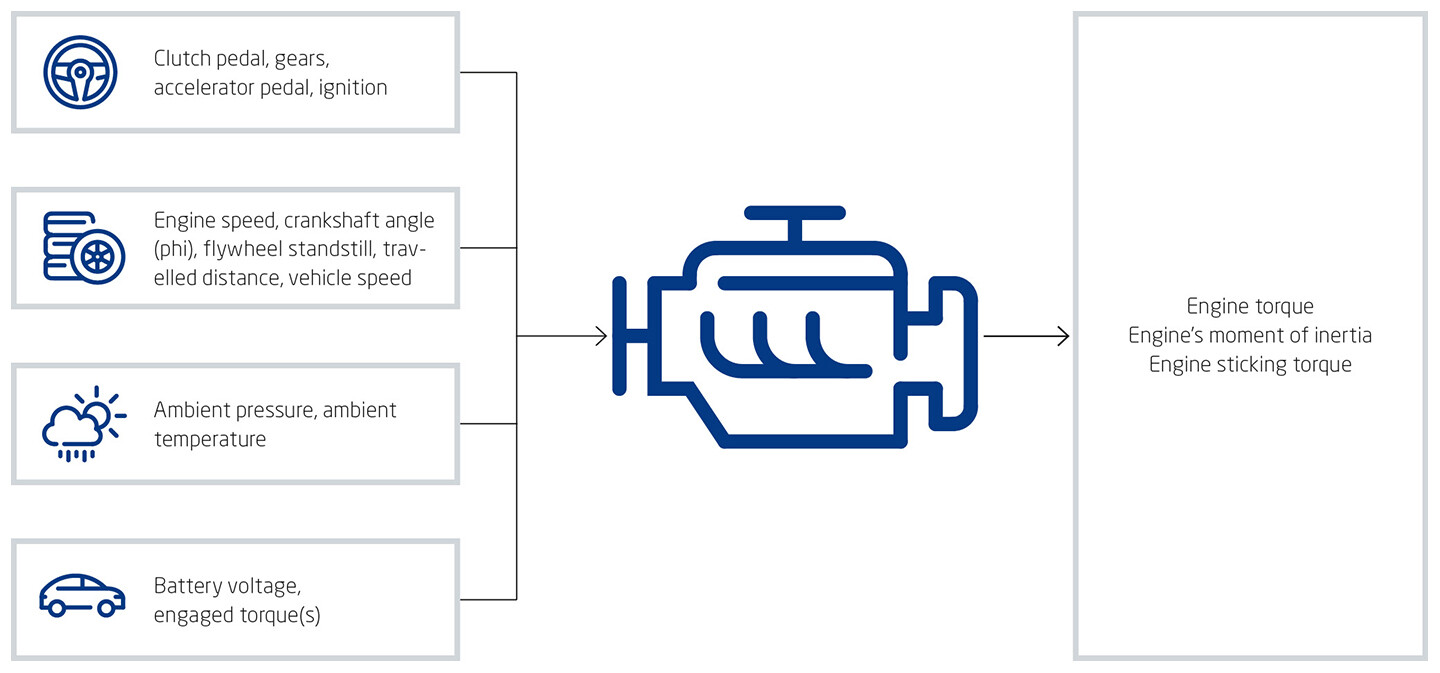

As an example, the engine model can be replaced with the detailed and accurate internal combustion engine model LABCAR-MODEL-ICE. This in-house Bosch model for testing and pre-calibrating gasoline, diesel, and CNG engines includes the main subsystems of an ICE – that is, the intake/ exhaust, fuel, combustion, and after-treatment systems. It provides variables at each sublevel for the customer to parameterize and to achieve the desired engine specifications. LABCAR-MODEL-ICE is a richly detailed mathematical and data-driven model that calculates engine parameters (see Fig.) such as torque, moment of inertia, RPM, and the like based on various vehicle input parameters and the ECU control logic.

LABCAR VVTB-ICE models in action

Tata Motors is using the VVTB-ICE model pairs to simulate the vehicle and internal combustion engine environment in the test system. ETAS India and the RBEI (Robert Bosch Engineering and Business Solutions) Global Testing Team tapped its engine parameterization capabilities for the customer vehicle lines for both diesel and gasoline engines. The focus of parameterization was on error-free (nil DTCs) verification of functionalities required by the team. The gasoline engine was parameterized for the Bosch ECU. During the acceptance phase, the customer team randomly verified the various functionalities to ensure smooth operation. VVTB and ICE models proved highly stable during prolonged runs, yielding accurate and consistent results at every point of simulation. ETAS Real-Time PC (RTPC) features a high-performance computation platform that enables highly complex models to be run at a higher resolution in order to obtain more accurate results.

With this real-time closed-loop simulation, the team was able to verify the majority of all functions for cases that do not require a real vehicle. The team was also able to conduct repetitive tests and multiple test runs, which is hardly feasible with an actual vehicle. Another benefit of an accurate closed-loop simulation is the option of running the vehicle at different conditions such as high speed, high RPM for longer periods, and so on. The team was also able to conduct several auto-mated tests quickly in the test system that otherwise would have required protracted manual tests.

Outlook

Accurate, high-fidelity simulations are an important asset for all system testing requirements. LABCAR models are built to meet these market needs. Paired with advanced ETAS tools like ETAS ASCMO-MOCA and engineering services, LABCAR-MODEL-ICE and -VVTB can serve to pre-calibrate EMS software in a HiL system. The team is currently validating the various ECUs across the vehicle network for different platforms. It benefits from accelerated automated validation with increased accuracy. This will surely expedite testing and support rollout of new vehicles with more mature ECU software. With advanced solutions, the team is well prepared to handle the validation challenges of the future.

Authors

Myrtle Binil R is Application Field Manager for Test and Validation Solutions at ETAS Automotive India Pvt. Ltd.

Harshvardhan Joshi is Key Account Manager at ETAS Automotive India Pvt. Ltd.

Further information

LABCAR-MODEL

-

Complex engine simulation using LABCAR-MODEL Download

Complex engine simulation using LABCAR-MODEL Download