New domains require new models

LABCAR-MODEL family of products now includes fuel cell model

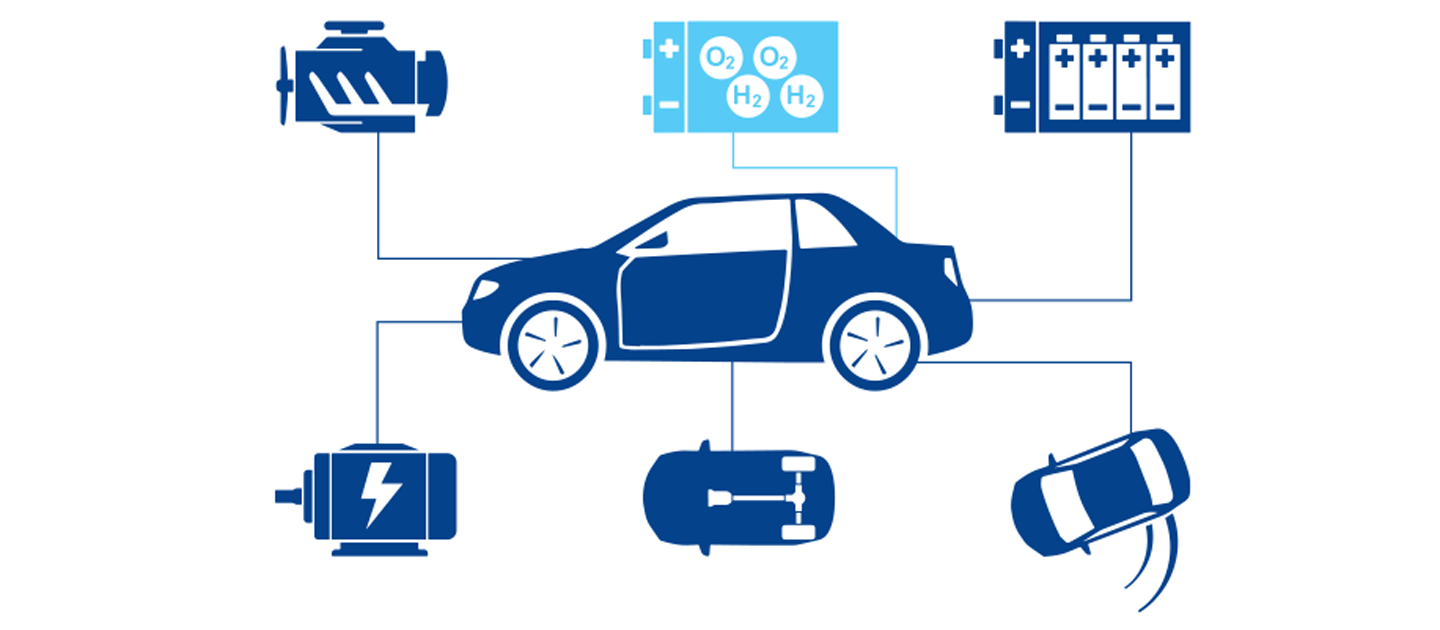

The twin tasks of significantly reducing greenhouse gas emissions from road transport and developing alternative vehicle drive systems pose a major challenge for the automotive industry. As an emission-free source of energy, the fuel cell is a promising candidate. Following years of research, ETAS has developed a simulation model of fuel cell systems for Hardware-in-the-Loop and Software-in-the-Loop tests. This model offers an efficient means of testing fuel cell ECUs and their operating strategies.

The German government’s Climate Action Plan 2050 aims to achieve a 40 to 42 percent reduction in greenhouse gas emissions from road transport by 2030 compared to 1990 levels. This goal covers emissions from cars, light commercial and heavy goods vehicles, and public transport. The development of hybrid and electric vehicles has led to electrification of the powertrain, which favors the use of fuel cells in the automotive sector.

In a fuel cell, hydrogen and oxygen react to produce electricity, heat, and water. This reaction does not produce any greenhouse gases, so there are no harmful emissions. The available energy density, however, is comparable to that of conventional fuels. To achieve the level of performance required by the automotive industry, individual fuel cells are assembled into modules known as “stacks.” This allows engineers to prepare fuel cell systems for different performance classes, for example for commercial vehicles or passenger vehicles.

Operating this kind of energy source safely in a vehicle requires a new component control unit known as a fuel cell control unit (FCCU). This maintains efficient fuel consumption and controls the amount of power generated by regulating the supply of hydrogen and oxygen. Unlike established engine control units, which have decades of development behind them, the FCCU must be made production-ready within just a few years, including development of all the open and closed-loop control and diagnostic functions. To enable rapid development cycles, it is essential to test and validate FCCUs and their operating strategies in a virtual fuel cell system – for example, using Hardwarein-the-Loop (HiL) or Software-in-the-Loop (SiL) set-ups.

As part of a doctoral thesis, ETAS and the University of Stuttgart developed a simulation model for fuel cell systems: ETAS LABCAR-MODEL-FC. Special emphasis was placed on achieving simple parameterization of the complex electrochemical processes within a fuel cell on the basis of easily accessible parameters. The model is geared to the specific requirements of the automotive industry, such as cold start behavior and water management.

Thanks to the use of advanced numerical solvers, the simulation model provides insights into water, temperature, and current distribution within the stack. This spatial resolution also facilitates the observation of non-linear effects, enabling even complex control functions to be tested in the FCCU.

LABCAR-MODEL-FC is specifically designed for use in LABCAR HiL systems and in COSYM SiL virtualization solutions. To enable deployment in these scenarios, the developers paid particular attention to real-time capable implementation. The result of their work, LABCAR-MODEL-FC, represents a realistic model of a fuel cell system for testing and validating an FCCU.

Summary

The LABCAR-MODEL-FC fuel cell model from ETAS is a truly cutting-edge product. It provides the perfect solution for performing efficient and reliable testing of ECUs for fuel cell drive systems both now and in the future. This is just one of the tangible contributions ETAS is making toward the development of e-mobility.

Author

Dr. rer. nat. Martin Rosing is Product Manager in the field of Test and Validation at ETAS GmbH.

Scientifically sound: LABCAR-MODEL-FC

Using a real fuel cell to test and validate ECUs for fuel cell drive systems is not only costly and time-consuming, but also potentially hazardous. LABCAR-MODEL-FC is a new simulation model developed by ETAS that specifically caters to the needs of the automotive industry. The model is based on a thesis jointly supervised by ETAS and the University of Stuttgart. It therefore combines a solid scientific basis with a practical focus – a product made by engineers, for engineers.