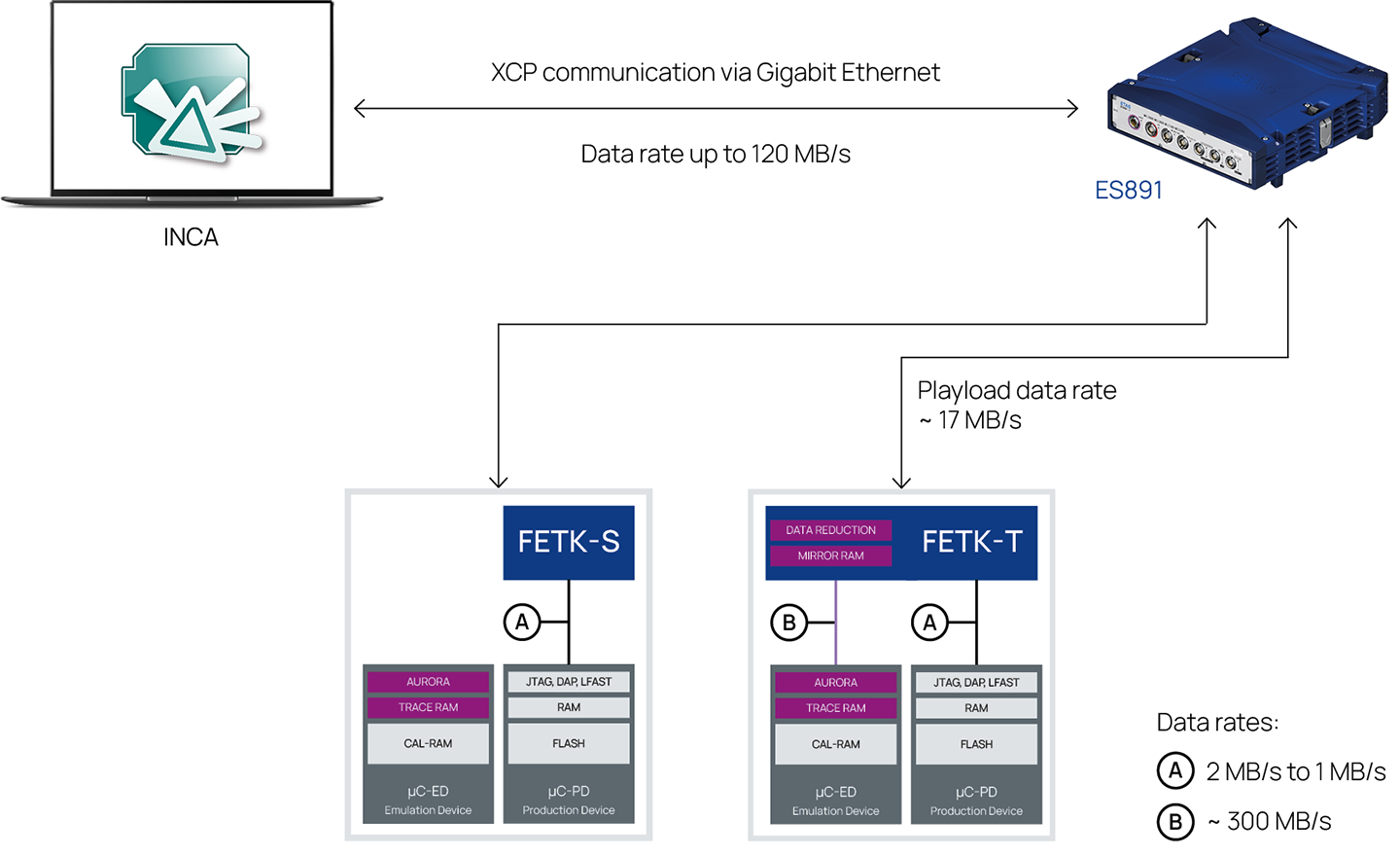

The FETK records data of the ECU in the vehicle or at the test bench via a microcontroller interface and transfers the data to the ES891 module. From there, these data together with data from other sources are transferred to a PC or notebook, where the data are processed online in the INCA environment. In doing so, the data is transported during the complete distance from FETK to INCA-PC via Gigabit Ethernet. Via the same transmission path parameters can be changed in the ECU by the user or by an automation with INCA.

For measurement purposes, the FETK-T allows users to attain maximum data throughput. The measurement values can be captured from the ECU at a raw data rate of up to 300 Mbit/s via the AURORA Trace/ interface. This has almost no effects on the runtime behavior of the microcontroller in the ECU, because Trace data is generated independently of the ECU program through automatic copying of the values of the relevant measurement signals, which the µC cores write to RAM cells. In FETK-T the trace data, which consists of time stamps, memory addresses, values, and trigger events, are written to a mirror RAM. There they are selected from the various measurement grids with respect to trigger time and thereby reduced. Currently, during transmission of the reduced data, speeds already reach 20 MB/s over the entire route from FETK to the INCA V7.2 application on the host computer. Thanks to the µC trace mechanism’s high raw data rate, the FETK-T is also capable of recording signals from control system processes with repetition frequencies of up to 200 kHz with time precision. For prototyping and configuration purposes, both FETK-S and FETK-T use the microcontroller’s debug interface.

Through its µC connection via debug interface, FETK-S delivers a measurement performance that is perfectly sufficient for many calibration tasks. With a small 46 mm x 25 mm housing, this FETK model is ideal for installation in production ECU housings. This allows companies to reduce the costs of calibration projects.