- Generation of Type 1, Type 2, and Type 3 virtual ECUs as FMU

- Cost savings through integration into existing infrastructures and CX toolchains

- Designed for easy collaboration with suppliers and partners

- For AUTOSAR Classic and Non-AUTOSAR software

Why VECU-BUILDER?

Speed and flexibility are the keys for the development of software-defined vehicles in DevOps development cycles. With cloud-based toolchains and virtual test environments, radical increases in development efficiency are possible while at the same time providing the highest level of safety.

A central role in virtualization is played by virtual ECUs combined with automated and parallelized test setups, designed for debugging, variable testing, and execution speed. They allow Continuous Integration (CI) of software regardless of existing hardware constraints, within simulated environments.

ETAS VECU-BUILDER is a tool to generate virtual ECU(s) as FMU for verification and validation of automotive microcontroller software in Software-in-the-Loop (SIL) setups.

The following paragraphs describe the tool, its capabilities, and some customer applications.

VECU-BUILDER from ETAS

VECU-BUILDER facilitates the creation of self-contained runnable virtual ECUs with a FMI 2.0/-3.0 for Co-simulation interface. This standardized interface enables the integration into existing testing tool chains, as well as wider OEM and supplier collaboration.

Input sources may be AUTOSAR-compliant source codes, Non-AUTOSAR-compliant source code and even PC binaries.

You want to know exactly how the VECU-BUILDER works?

Visit our playlist with many interesting tutorial videos!

The true value of VECU-BUILDER comes from a tailored approach by an international team of expert consultants and engineers. Based on the customers’ needs it is possible to generate different types of virtual ECUs (see below).

Have we sparked your interest?

We are happy to answer all your questions.

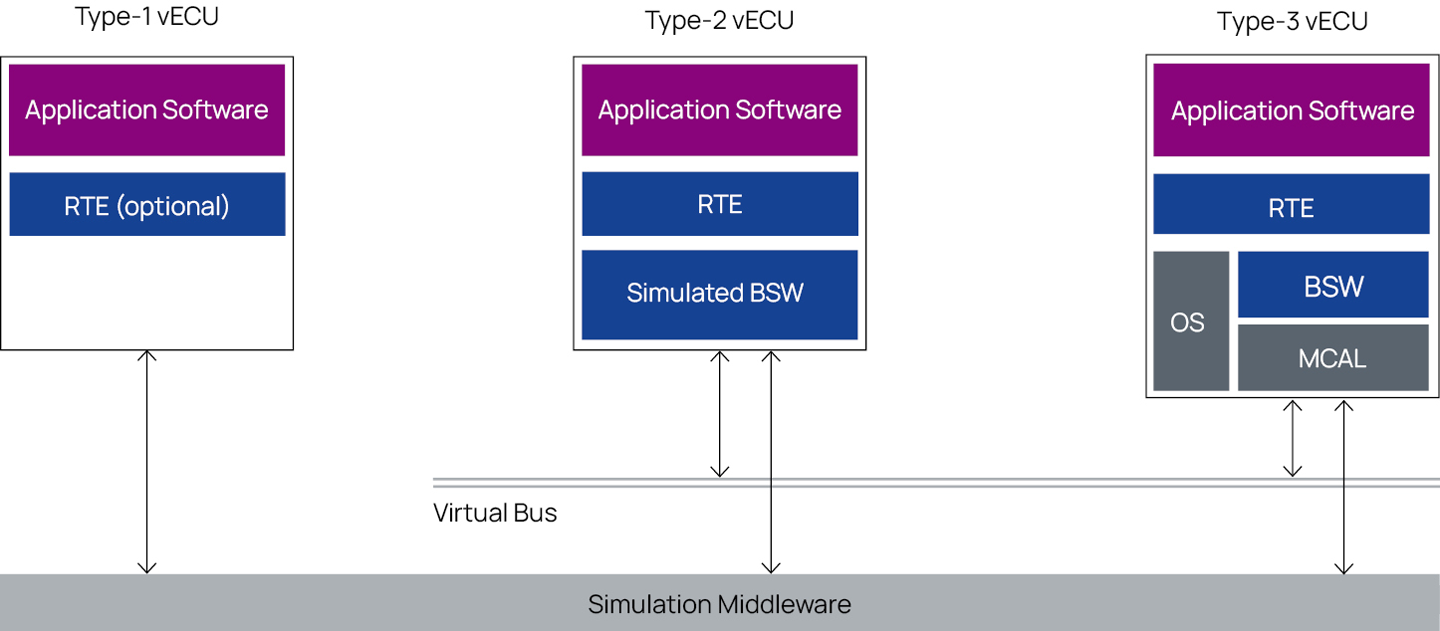

The effective creation of virtual ECUs and systems often involves a process of incremental development. Each vECU Type is defined by a gradual transition from simulation-specific code to the complete production code intended for a target ECU(s). Types 1-3 are executable on a standard PC architecture independent of the actual ECU hardware. This facilitates a significant speed up of ECU development through accelerated simulation speeds and easy debugging.

Type 1

A type 1 vECU only contains the application software (ASW) and, optionally, the runtime environment (RTE). It communicates at signal level.

Type 1 vECUs enable the application software to be tested and validated as early as possible in the development cycle when the hardware is still under development. These vECUs are also used for rapid control prototyping.

Type 2

In addition to the application software and the runtime environment, a type 2 vECU also contains simulation-specific basic software (BSW). Communication takes place at both signal and bus network level.

This enables the testing of a wider range of application software across multiple networked vECUs.

Type 3

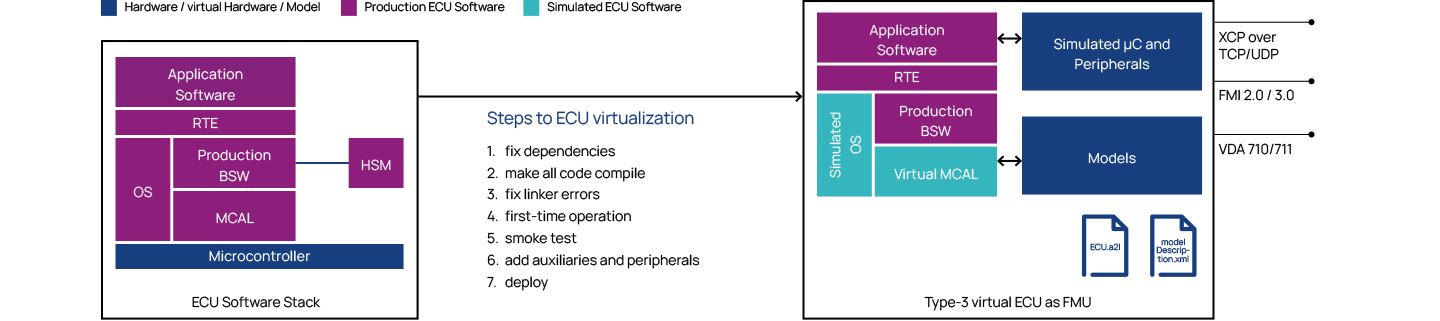

A type 3 vECU contains all software components that have no fixed reference to the microcontroller hardware. This includes application software, runtime environment, the basic software of the series controller and other application-specific components, such as a hardware security module (HSM) or the operating system.

Type 3 vECUs are used for software integration tests and network testing.

As a global player in virtualization technology, ETAS is uniquely positioned to offer OEMs and suppliers considerable benefits. These include expedited development cycles, reduced costs, and increased efficiency.

- Speed up ECU development with an incremental approach to testing, debugging, and implementation.

- Reduce development costs by removing dependency upon hardware-intensive testing methods such as HiL.

- Further reduce time and cost implications with an adaptable approach to integration within existing infrastructures and proprietary requirements.

- Experience simplified collaboration with suppliers and partners with an approach that balances broad compatibility with a standards-based system architecture.

- Meet your specific success criteria with a tailored approach to vECU Types and build customization.

- Realize the full potential of a virtualized approach with ongoing consultation, support, and security testing from an international team.

Have we sparked your interest?

We are happy to answer all your questions.

Experience the benefits of virtualization with the seamless integration of VECU-BUILDER

ETAS empowers OEMs and suppliers to realize significant reductions in the time and cost of development cycles while increasing overall efficiency. This is a result of broad third-party compatibility and tailored virtualization solutions. VECU-BUILDER is the system of choice for the creation of virtual ECUs in automotive and commercial vehicle industry with an emphasis on seamless integration and standardized protocols.

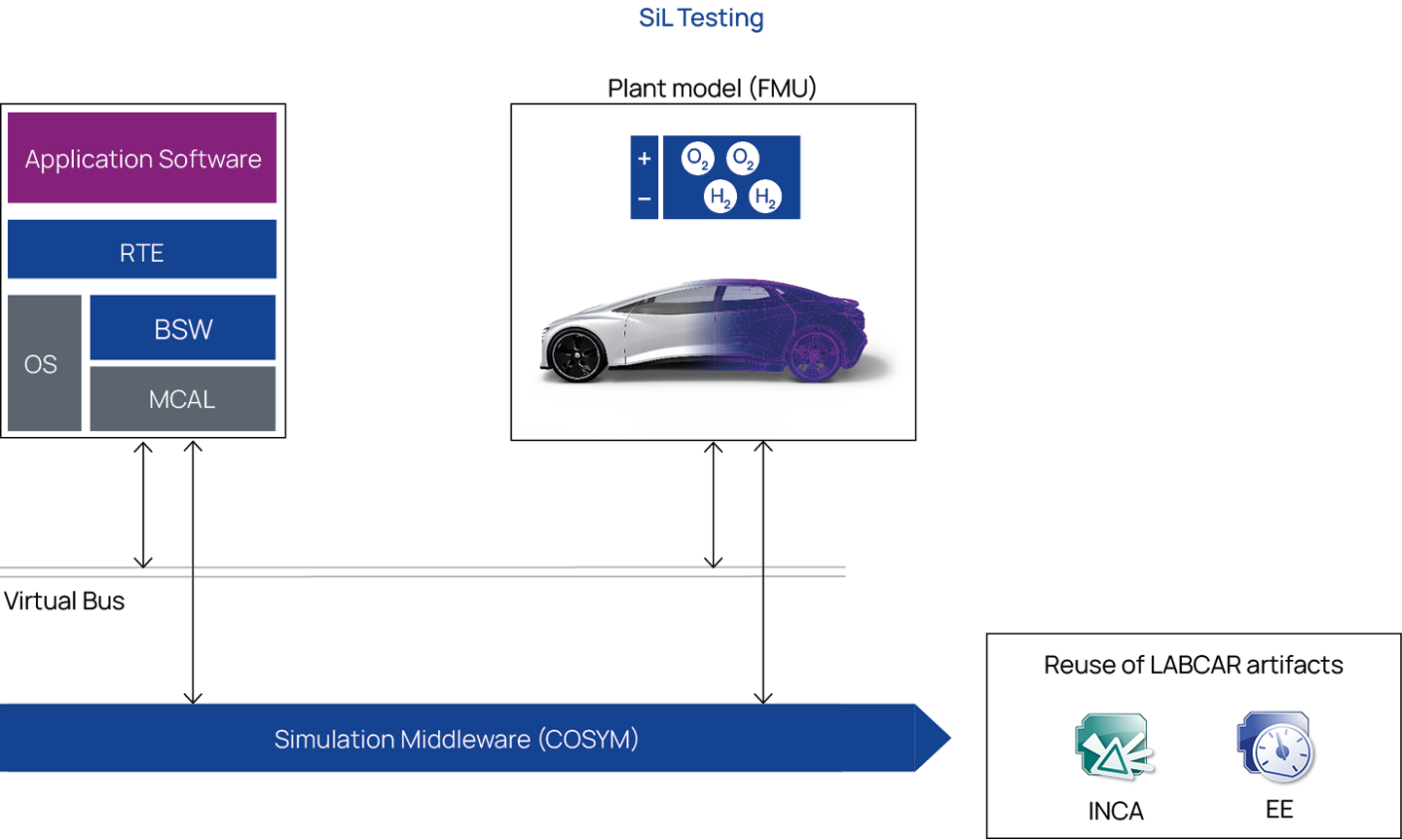

Virtual ECU for Fuel Cell Development

In this case, the OEM searched for a transition from HiL testing to SiL to exponentially increase simulation speed and overall testing efficiency, while keeping the existing test cases. Challenges were posed by the necessary integration of existing architecture with a vECU, including in-house AUTOSAR BSW and current HiL testing parameters.

ETAS leveraged the significant 3rd-party compatibility of VECU-BUILDER to successfully generate a virtual ECU compliant with automotive and proprietary requirements. This was achieved by integrating existing tooling and parameters into a custom Type-3 vECU. Success parameters were achieved with a closed SiL testing model capable of generating results 6-8x faster than the prior setup.

SiL for Smartphone Vehicle Access System

Overall testing effectiveness was hampered by severe cost and time constraints caused by a complex and ill-suited heterogenous HiL setup. Creation of a virtual ECU was complicated by data from multiple sources, including 3rd-party AUTOSAR BSW and non-AUTOSAR components.

ETAS VECU-BUILDER offers industry-leading flexibility and is capable of integrating all heterogeneous software parts into an FMU. ETAS was chosen as most flexible supplier for meeting the customer's requirements. Success parameters were achieved with an incremental build and debugging SiL model. The build reduced turnaround times from weeks to days and significantly cut overall development costs.

Have we sparked your interest?

We are happy to answer all your questions.