The ES63x Modules possess a high-performance sensor heater. The ES63x modules control and regulate the sensor heater. The power supply delivers a heating current of 5 A in the voltage range between 0 V and 18 V, which makes it possible to bring the fast LSU ADV sensor up to operating temperature within 5 s. In order to spare the measurement probe, it is possible to continue operating the sensor heating after the modules’ measurement unit has been switched off. Equally, the heating can be switched on independently of the measurement by means of an external signal – typically “Engine On.” The Lambda Modules monitor the sensor’s temperature and internal resistance and output this information.

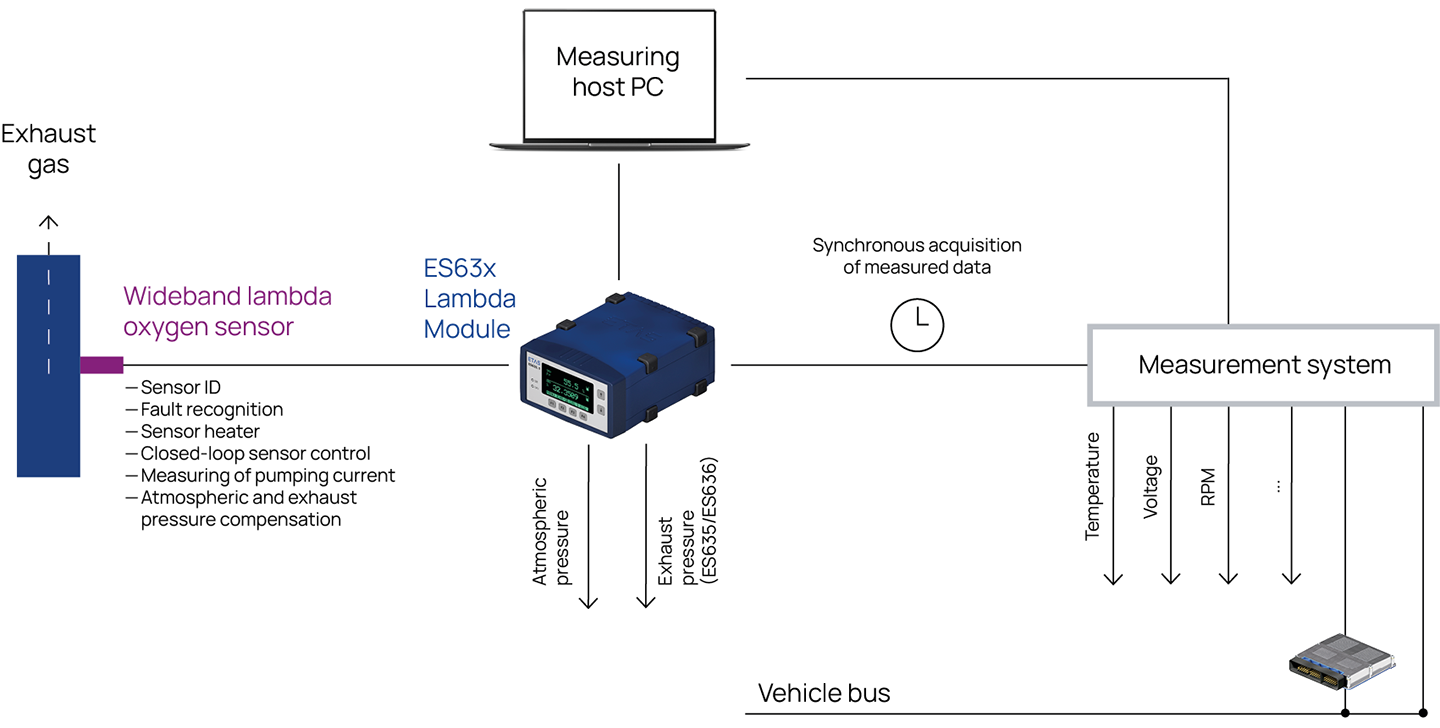

The ES630/ES635 (1 channel) and ES631/ES636 (2 channels) Lambda Modules are connected to an LSU broadband lambda sensor. Lambda Modules are connected to a wideband lambda oxygen sensor. To compensate for pressure effects, all models provide a built-in sensor. As an option, ES635 and ES636 modules can be connected to a pressure sensor mounted in the exhaust system.

Measurement of atmospheric and exhaust pressure

All ES63x modules are capable of measuring the atmospheric pressure by means of an integrated sensor. To the modules ES635 and ES636, an external pressure sensor can be connected in addition. With this external sensor, pressure changes within the exhaust or air system can be measured. Influences of atmospheric and exhaust pressure changes on the lambda measurement can automatically be compensated by the lambda modules. Independently of lambda measuring, pressure signals are available for further analyses. As an example, on the basis of an air pressure measurement, the height profile of a test drive can be recorded. By means of the external sensor, the pressure in the turbo charger can be measured.

Broad range of application

All module variants possess a display and can be used on their own. Grouped around the display, there are six control buttons, which can be used to configure the device and the display. The display shows two measurement values and the operating mode at the same time. In addition, it is possible to output a linearized signal with voltage values in the range between 0 V and 10 V at an analog output.

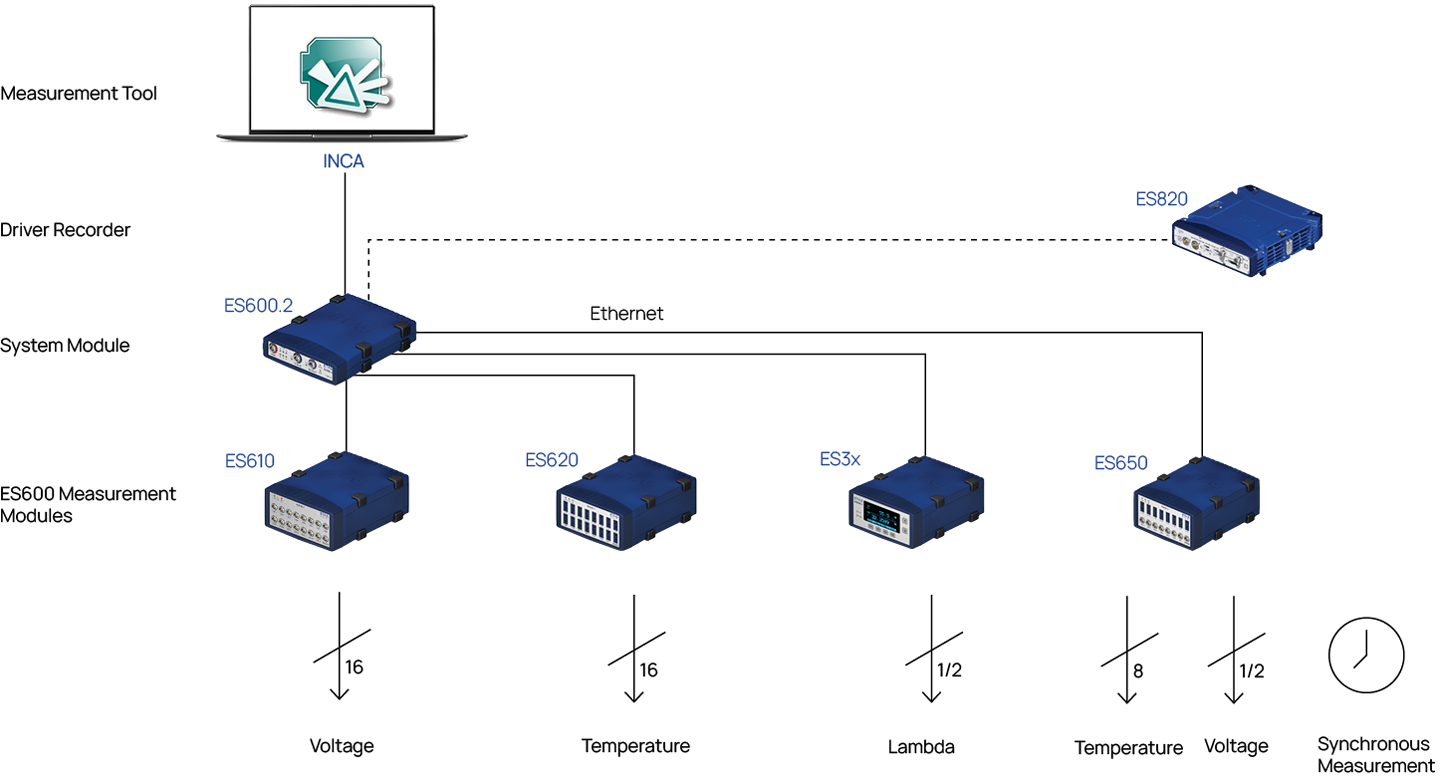

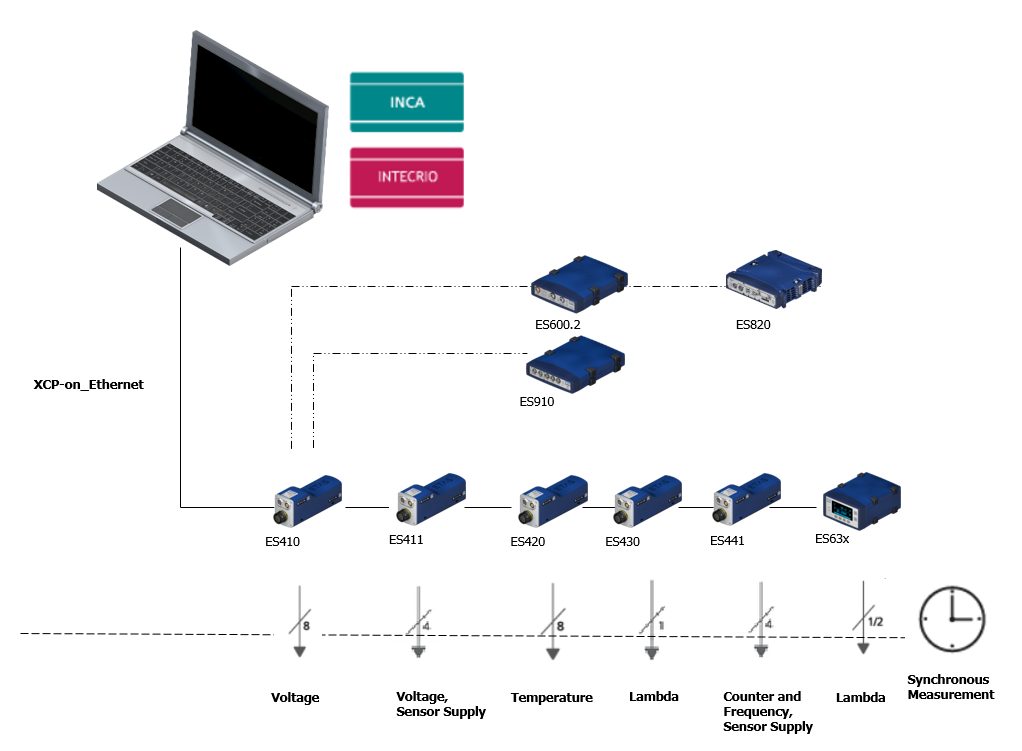

Via Ethernet, the ES63x Lambda Modules can be connected directly to a PC with suitable measurement software or with other ETAS compact hardware modules. The Lambda Modules supply the measuring host PC simultaneously with values for various measured variables. Their data acquisition is automatically synchronized with other ETAS measurement modules.

The Lambda Modules are supported by ETAS’s INCA development tools, the integrated environment for measurement, ECU calibration, and diagnostics, the INTECRIO and ASCET-RP prototyping tools, and the ES910 prototyping and interface module. All devices have an RS-232 interface and support the SMB protocol. If required, LA4 Lambda Modules can be easily replaced by ES63x modules in existing measurement configurations.

By virtue of XCP-on-Ethernet, the Lambda Modules provide a standardized data transmission interface through which the devices can easily be integrated into existing measurement environments. The vehicle-compatible modules can be operated in an expanded temperature range between -40 °C (-40 °F) and 70 °C (158 °F).

Lambda Oxygen Sensors

The functional principle of lambda oxygen sensors is based on the oxygen ion conductance of zirconium oxide at high temperatures. In the case of wideband zirconia sensors, the oxygen concentration of the test gas inside the Nernst cell is set to l = 1. This is accomplished by pumping – i.e., injecting or extracting – oxygen ions into or from the test gas. The size and direction of the pumping current facilitate the accurate definition of lambda values. Wideband zirconia lambda sensors provide oxygen control in both rich and lean mixture ranges. Due to their continuous measuring characteristics, these sensors enhance the dynamics of the classic lambda control loop. The LSU wideband sensors from Bosch work reliably at temperatures above 600 °C (1112 °F). They are designed for a permanent duty cycle at exhaust gas temperatures of up to 930 °C (1706 °F) and short-term peaks of up to 1030 °C (1886 °F). As the sensors incorporate an internal heater, they are operational with cold exhaust flow and functional within a few seconds of starting a cold engine. The effect of the heater minimizes the influence of the exhaust temperature on the sensor signal.

Reference Measurement

Automotive vehicle and engine development deploys wideband zirconia probes in conjunction with precision lambda oxygen measuring devices, which determine the lambda value from the pumping current, for test and calibration purposes. The lambda measurements obtained in this manner become the basis for calibrating the lambda control of engine control units.

For over a decade, ETAS has been offering lambda modules for Bosch-manufactured LSU wideband lambda oxygen sensors. The lambda reference instruments are standard parts of the measuring instrumentation for test bench and in-car testing.